Why is Adequate Ventilation so Important?

Adequate ventilation within a building ensures good air quality, by removing toxins and CO2, and also helps to control humidity, thus reducing the risk of condensation. Energy efficiency and thermal comfort can also be enhanced. Air quality can be affected by a number of impurities, such as low-level irritants (dust, pollen) right through to radon and volatile organic compounds. In humid or colder areas, and particularly in uninsulated buildings, there is also a significant potential for condensation when humidity levels are too high, and this can result in mould growth and various health issues. Building fabric can also be affected by moisture and deteriorate, reducing the life of a building and adding to life-cycle costs.

Why Use Mechanical Ventilation?

A mechanical ventilation system can:

•remove stale air and introduce fresh air into a building assist with reducing indoor humidity levels

•reduce incoming pollutants, when effective filtration is included

•remove indoor pollutants, including CO2 and VOCs from off-gassing of materials such as those used in furniture and finishes.

Studies show that to ensure adequate ventilation by natural means, the windows in a reasonably well-sealed building would have to be opened at least four to six times a day for a reasonable amount of time.

Who Does it Work For?

One of the most important things to get right before introducing a MVHR system is your building sealing—for what is the point in controlling the ventilation and attempting heat recovery when your building leaks like a sieve anyway? It’s similar to turning on the heater while you have all the windows open— fighting the classic ‘losing battle’.

In order to be successful, ultra-low energy buildings require a very good level of airtightness. Once a building is airtight, it then becomes necessary to introduce ventilation in order to make the building habitable.

Types of Systems

The simplest mechanical ventilation system uses exhaust fans only, with fixed inlets to provide makeup air. There is no heat exchange on this system, so incoming air is the same temperature as ambient. Exhaust points would likely be provided in areas such as bathrooms and kitchens.

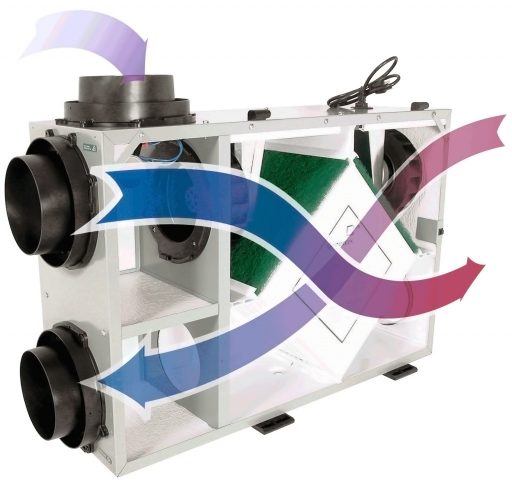

Another simple system is a two-way ventilator, which operates on a push-pull basis to generate a flow of supply and exhaust. These ventilation systems operate with one fan unit exhausting and the other supplying air.

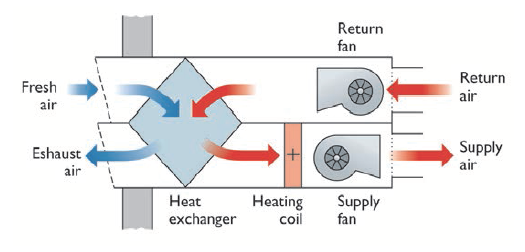

An integrated heat recovery heat exchange bank is used to transfer heat between exhaust and supply air streams.

At the other end of the scale, a fully-ducted ventilation system is the most effective solution, and utilises fully controlled and balanced ventilation. This type of system is most effective when applied in a well-sealed building, where other infiltration sources are reduced (note: this does not preclude openable windows!) These systems supply fresh, filtered air to the building, where it then flows through the building before being exhausted back to outside, thereby removing hot or humid air. The air volume supplied is balanced with the exhaust.

The most efficient way to operate such a system is to include heat exchange, whereby thermal energy is transferred between the outgoing and incoming air streams, keeping the internal conditions stable and retaining that energy. Bypass arrangements are possible on these heat exchangers, to take advantage of times when outdoor conditions are good enough for direct air supply.

Heating and/or cooling coils can be added to the more complex MVHR systems, and radiant or refrigerant systems (split systems or radiant panels) can be located internally to provide any additional heating or cooling requirements.

What to Look For

Like everything, it’s about selecting the system that’s right for the application. There is reduced benefit from installing a heat recovery system if the issue of building sealing first hasn’t been addressed, as uncontrolled air infiltration will negate the effectiveness of your mechanical system.

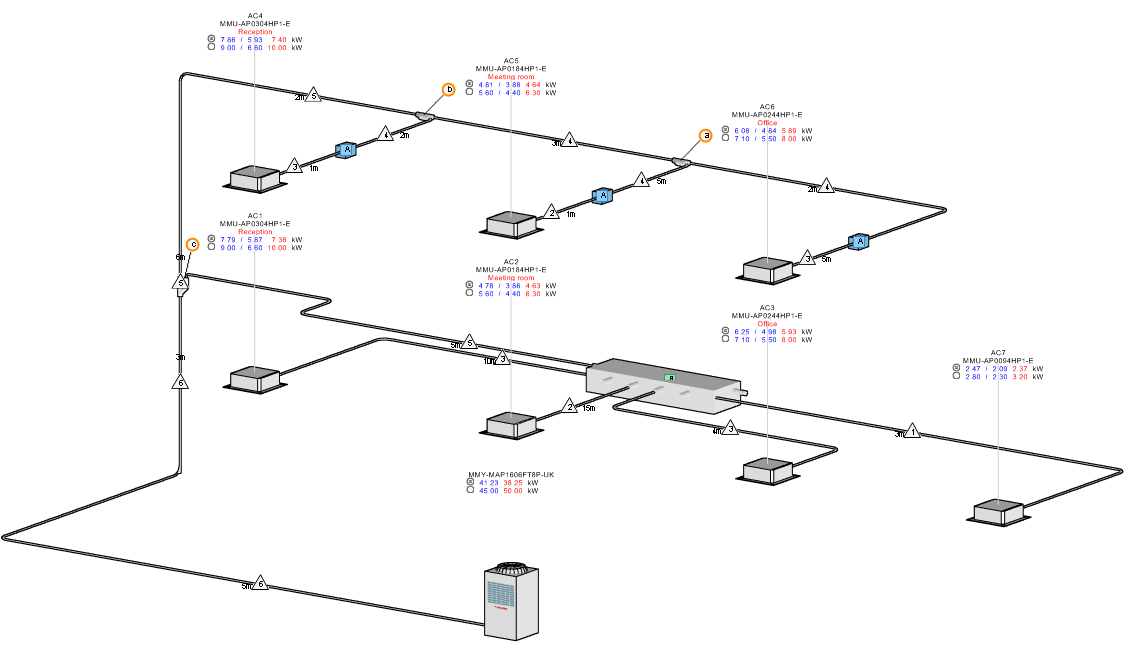

Units should be selected based on predicted ventilation requirements (a function of occupancy and heat loads) and then size.

The unit should be selected for high thermal exchanger efficiency. A good unit will have a sensible (related to temperature) heat exchange efficiency of greater than 80% (it can be up to 93%). However, a reasonable efficiency could be around 75% and such units will typically be more affordable.

Electrical efficiency should also be considered (energy consumption per m3 air delivery—less than 0.45 Wh/m³ is excellent).

Controls can be as complex or simple as desired.

For advice on ventilation please call us on Coventry Tel: 024 7624 9440 or email us at sales@chillaire.co.uk / 16 Lythalls Lane, Holbrook, Coventry, CV6 6FG